Vibration absorbing pad (rubber and polyurethane)

One of the most important problems in the operation of intra-city and inter-city railway lines is the creation of vibrations caused by the passage of the train. These vibrations, while damaging the infrastructure of the railway line, cause discomfort to the residents around the railway lines. Therefore, the buildings and historical monuments that are located near the subway and railways, under the influence of the dynamic stresses caused by the movement of the train, experience vibration and noise, and on the other hand, due to the rigid

Being the infrastructure and pavement in the subway, this high rigidity causes wear of the suspension system and more noise. Therefore, to reduce noise and vibrations in railway lines, pads are used under the rails and rail bindings.

Vibration absorbing pads can reduce vibrations by about 3 to 8 decibels. Vira Poish Sepid Company, the first exclusive manufacturer of carpets and vibration absorbing pads in the country, as the first creator of vibration absorbing pads in Iran, has taken steps to produce products in different types with different thicknesses and dimensions, and has a wide range of rail pads for any hardness required. , with different genders.

All kinds of pads produced by Danesh Banyan Vira Poish Sepid company including button pads, two and four hole pads with different materials; It is rubber and polyurethane.

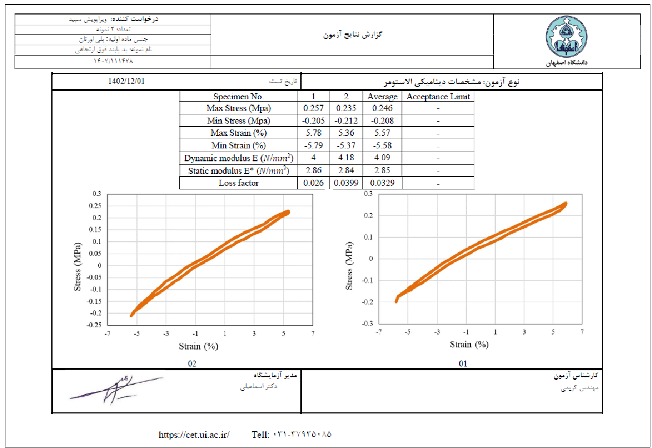

Technical Specifications

| Row | Material properties | Measured range | Test methods | comment |

| 1 | Tensile stress at break | 11.44.5- N/mm2 | DIN EN ISO 527-3/5/100 | Minimum Value |

| 2 | Water absorption | 0.33% | DIN 45673 | Minimum value |

| 4 | Dynamic modulus | 0.20 N/mm3 | DIN 45673 | Minimum value |

| 5 | Static modulus | 0.142N/mm3 | DIN 45673 | Minimum value |

| 7 | Mechanical loss factor | 0.329 | DIN 53513 | Depending on frequency, load and amplitude (reference value) |

| 8 | Elongation at break | 662.2% | DIN EN ISO 527-3/5/100 | Minimum value |

| 11 | Compression set | 5-11 % | EN ISO 1856 | 50 %, 23 °C, 70 h, 30 minutes after unloading |

| 12 | Density (D) | 1100 (kg/m3) | – | – |

| 14 | Volume electrical resistance | 3.31×107 | ASTM D257 |